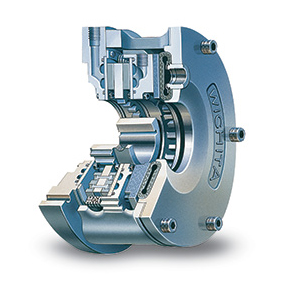

Wichita Kopper Kool Brake and Clutch

Wichita Energy & Offshore Oil Brochure

Kopper Kool Brakes Optimized for Drawworks Applications

Wichita Kopper Kool brake and clutch represent the ultimate design for very high heat dissipation in the most rugged tensioning applications. Torque levels are in direct proportion to air pressure, providing accurately controlled, continuous slip braking action.

• New HICO friction material provides higher torque

• Copper alloy wear plates increase heat transfer

• Balanced water flow for the highest thermal capacity

• Durable air tube design

• Long-lasting friction material

• Integral shaft sub-assembly for optimal drawworks performance

• Saltwater corrosion package available

• Compatible with major electronic drilling systems

• Airtube has less hysteresis than piston type actuators, making it ideal for automatic drilling systems

• Packaged system can be easily removed as a unit for service if required and/or quickly swapped out for maximum rig availability

• Adjustment for wear is easily accomplished by removing shims without any unit disassembly

• Optional: Wear detection is built into the package for external monitoring

Design advantages

• New friction material is longer lasting with less wear on mating copper. Consistent torque response results directly with air pressure applied. Mechanically retained friction pads can be changed in field.

• Copper has a greater heat transfer capacity than any other metal other than precious metals.

• Generated teeth, in addition to providing perfect alignment of rotating members, offer maximum sensitivity of torque to pressure relationship. All factors affecting torque are fully controlled. Tangential cooling grooves insure effective mixing of cooling water for best heat conductivity. Water volume of the jackets insures high water velocity, which reduces sedimentation and chemical formation. Maximum inlet pressure is 60 PSI.

• Close grain alloy iron jackets for coolant assure maximum resistance to corrosion.

• Releasing springs insure complete disengagement.

• By using a triple roto-coupling, the brake can be used as a constant slipping clutch.

• Flexible fiberglass pressure plate assures even distribution of pressure from actuator to braking surfaces, providing maximum contact area on friction surfaces.

• All coolant and air connections are external and easily accessible. Double outlets in center water jackets for multiple plate units 24” and larger.

• Air passages through brake greatly assist in keeping brake cool.

• Actuating member is a reinforced neoprene airtube which has no resistance to movement, resulting in immediate reaction with small pressure changes. Non-corrosion neoprene is unaffected by actuating medium.