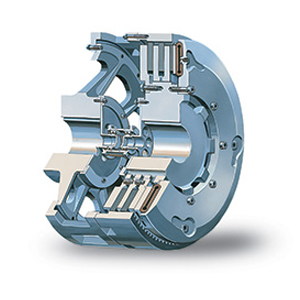

Grinding Mill Clutch

Wichita Grinding Mill Clutches are specially designed to provide quick, smooth starts with limited current surge for heavy duty grinding mills. The clutch is adaptable to remote control allowing centralized op er a tion through simple air or electric circuits.

• No adjustment or lubrictation

• Eliminates need for special high torque motors

• Torque capacity not affected by centrifugal force

• High heat dis si pa tion for jogging and inching

• New high coefficient, high energy absorbing friction material standard for grinding mill applications

The clutch’s primary role is to provide smooth starts during mill startup. However, as the mill is running, the clutch also serves as a torque “circuit breaker,” reducing costly repairs and downtime by protecting the pinion and ring gear from potential damage from large pieces of grinding material.

The Wichita airtube design combines all the best features of a disc type clutch with all the advantages of direct air engagement. It is the simplest and most trouble-free method of applying air pressure yet designed.

Units feature a quick-change ring which slides open to allow easier access to friction discs when they need to be replaced. The clutch is adaptable to remote control allowing centralized operation through simple air or electric circuits.

An optional axial locking device that prevents clutch pre-engagement by holding the electric motor shaft during float conditions is also available.

Models are offered in a wide range of sizes from 11” to 72” diameters with torque ratings from 42,294 in.lbs. (4,779 Nm) to 30,955,750 in.lbs. (3,497,530 Nm).

Grinding Mill Clutches for the Mining Industry